Functions and features

CD-2008II Full auto wet wipe machine all machine electric control system adopts imported high quality brand, using keyence operation control system, system optimization, simple operation, stable.All the process from raw material to the finished product of packing, all on the machine finishing, and quick production process, hygienically.

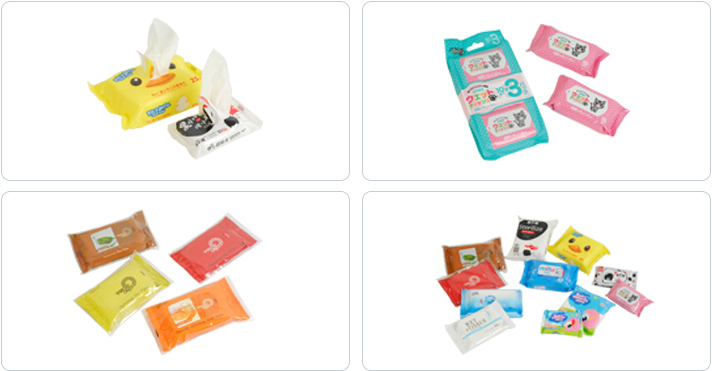

Work flow: raw material pneumatic unwinding→tension control→Web guiding→folding→quantitative wetting→cutting in size→horizontally folded in half→stacking and counting pieces→piles doubling conveyor unit→packaging film pouching and labeling→bag making→into the bag packaging→sealing→output finished products.

◎This machine is with automatic unwinding and online slitting,non-stop automatic splicing(non-woven material), automatic alarm when raw materials break down, raw materials web-guiding system, quantitative wetting, cloth cutter independent adjustment, convenience of operation changing, saving cost;

◎Folding adopts roll fold type, each piece wet wipe neat and beautiful, high speed stacker (patented product), stacking tidy and beautiful, convenient for packing;

◎Two packing film roll frames, save time of change the film;

◎Labeling double system device, automatic transform when one labeling finished also the other labeling unit can be used for small label;

◎Adjustable bag making former;

◎Servo motor control transverse sealing mechanism, speed fast , sealing more tight and beautiful;

◎Pressure protection unit, bounce off automatically, avoid damaging the sealing cutter, and reduce material waste.

CN

CN EN

EN RU

RU AE

AE FR

FR PT

PT ES

ES VE

VE