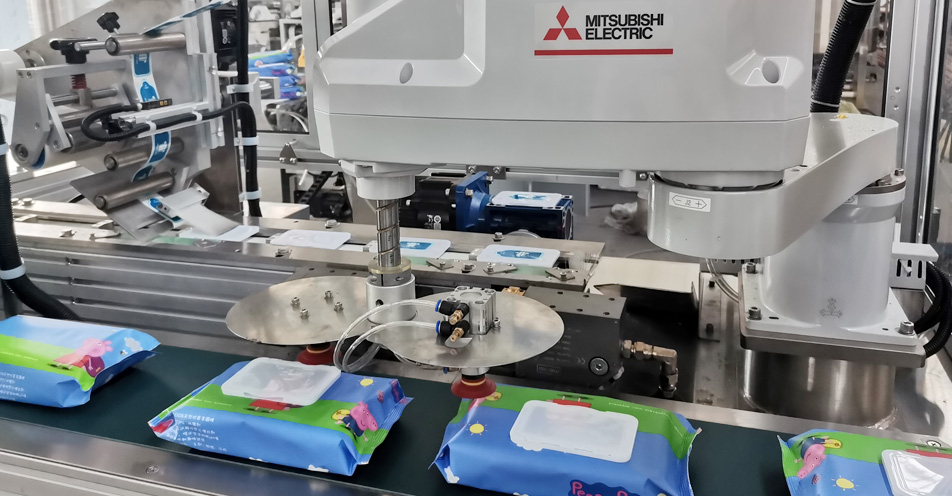

This machine uses Mitsubishi robot's high-rigidity manipulator arm, a perfect combination of visual recognition technology and conveyor belt following technology. A series of actions such as automatic lid removal, labeling, gluing, and lid sticking can be completed online. When changing the lid specifications, the touch screen operation is switched. Save manpower, thereby reducing labor costs. Greatly improve production efficiency.

Functions and features

◎The Mitsubishi robot arm adopts a new type of servo control;

◎ High speed, high precision, high performance;

◎ High product yield, saving raw materials;

◎ It is a cost-effective product to save manpower and reduce costs;

◎ The mechanical structure is simplified, the structure is stable, and the breakdown is low;

◎ Visual positioning system: color high-definition camera, precise coordinates.

CN

CN EN

EN RU

RU AE

AE FR

FR PT

PT ES

ES VE

VE